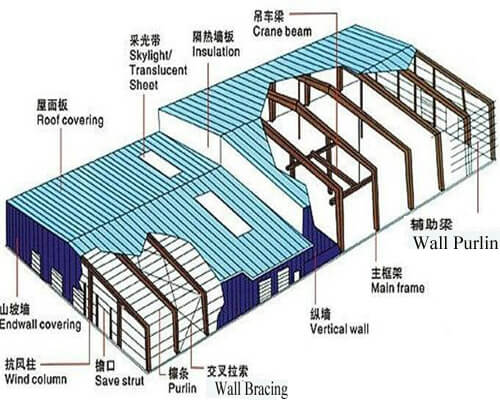

Steel Structure Building Components

Steel structure building is a new type of building structure system. The building structure system is formed by the main framework through linking up the H beam,Bracing ,C purline,Z purline,and other steel components. Roof and wall using a variety of panels together with other components such as windows and doors .Steel Structure Building Components as follows:

1.Main Structure

Steel Column

Roof Beam

Wind Column

Crane Beam

2.Secondary Structure

Purlin ( C section or Z section

Tie Beam

Sag rod

Flange Bracing

Bracing ( Roof Horizental Bracing , Wall Cross Bracing)

3. Enclosed System

Corrugated single color sheet

Wire mesh

Insulation materials

Edge trim

4. Fastener

1)Foot Bolt,2)High Strength Bolt,3)Normal Bolt,4)self-tapping nail ,5)Waterproof rivet ,6)Structural adhesive.

Figure-1 Steel Structure Building Components

1. Steel Column

Steel Column according the formed type can divided in two categories

1)solid web column : H section column that the web plate is the rectangular shape or tapered column that web plate is trapezium ,easily fabrication and safety.

2)Space Column

space column also called Latticed Column , difficult for fabrication ,reasonable for loading and light weight.

Figure-2 Solid Web Column Figure-3 Latticed Column

2. Steel Beam

Steel beam welded by steel plate or hot roller beam ,mainly used welded type H section beam,the top and bottom flange plate and web plate welded as H section beam .

Figure-4 Steel Structure Beam

3.Wind Column

Wind Column is the structure on the gable wall , wind column used for transfer the wind load on gable wall ,top through hinge connected with roof beam transfer to the roof system and as for the whole bent

load bearing structural,bottom throught connected with foundation transfer to foundation.

Arrangement method of wind column

arranged according Light Steel Plane Frame Structure : the foot of wind column hinge joint or rigid joint with foundation ,according the arrangement method ,roof load beared by steel frame and wind column together ,wind column bear the wind load and vertical load .

Figure-5 Wind Column

4.Crane Beam

crane beam is used to load the crane inside the workshp,crane beam is roadbed that support the driving of crane ,crane beam similiar as steel beam ,the diffirent is the web plate of crane beam welding stiffer plate which used provided support force when lifting cargo.

Figure-6 Crane Beam

5.C Purlin (C section steel)

C Purlin is C section steel that formed by galvanized steel sheet ,C Purlin widely used for fixed wall and roof panel

Figure-7 C Purlin

6.Z Purlin (Z section steel)

Z purlin with high strength ,save the steel materials ,quickly and easily for erection.Z purlin used for big span

7.Tie Beam

Tie Beam is the connecting rod in the horizontal length of building,tie beam used to resistant the longitudinal force.

8.Sag Rod

Sag rod used for tension and keep the purlin lateral stable,at same time arrange tension bracing in some area , it is sag rod plus sleeve pipe.

Figure-12 Sag rod

9.Flange Bracing

Flange bracing is the 45 degree diagonal bracing that connected with steel beam and purlin

10.Horizental Bracing

Horizental bracing is the horizental truss that arranged on side or middle of roof,horizental bracing used to enlarge the integral rigidity of roof and enlarge the lateral stability of frame.

11.Column Bracing

Column Bracing is ensure the overall stability of the building structure, improving the lateral stiffness and the transfer of vertical horizontal force ,transfer the vertical wind loading to column.

12.Wire mesh

Wire mesh used to support and stable the roof glass wool insulation materials.

Steel Structure roof system:

1)Single Color sheet , roof sheet used corrugated color sheet , such as V840Type

2)Single Color sheet + Glass wool insulation + wire mesh

Figure-17 Roof System

13.Insulation materials

Glass wool insulation used for heat preservation and insulation on roof .

Figure-18 Glass Wool Insulation Materials

14.Single Color sheet

Single color sheet also called corrugated color coated sheet which used as wall and roof of the industrial building ,warehouse,roof of the big span building.

Figure-19 Corrugated Color Sheet

15.Foot bolt

Foot bolt is J or L shape pre-embedded in concrete to connected with steel column,foot bolt fabricated as Q235B steel rod,the embedded depth is 25 times of diameter .

16.High Strength bolt

Friction type high-strength bolt :used for the connection of frame beam,column,solid web beam,the connection of crane beam in industrial workshop.

Bearing type high-tensile bolt :Can be used to allow a small amount of sliding in the static load structure or indirectly bear the load in the component of the shear connection.

Tensile strength bolt:Bolt tension, the fatigue strength is low, under the action of dynamic load, its carrying capacity is not more than 0.6P.

17.Normal Bolt

Normal bolt not used as bearing member ,used as connection during installation,normal bolt mainly used the connection of wall and roof purlin.

Figure-22 Normal Bolt

18.Self-tapping nail

Wall and roof panel of steel building fixed by self-tapping nail

Figure-22 Self-tapping nail

1.Main Structure

Steel Column

Roof Beam

Wind Column

Crane Beam

2.Secondary Structure

Purlin ( C section or Z section

Tie Beam

Sag rod

Flange Bracing

Bracing ( Roof Horizental Bracing , Wall Cross Bracing)

3. Enclosed System

Corrugated single color sheet

Wire mesh

Insulation materials

Edge trim

4. Fastener

1)Foot Bolt,2)High Strength Bolt,3)Normal Bolt,4)self-tapping nail ,5)Waterproof rivet ,6)Structural adhesive.

Figure-1 Steel Structure Building Components

1. Steel Column

Steel Column according the formed type can divided in two categories

1)solid web column : H section column that the web plate is the rectangular shape or tapered column that web plate is trapezium ,easily fabrication and safety.

2)Space Column

space column also called Latticed Column , difficult for fabrication ,reasonable for loading and light weight.

Figure-2 Solid Web Column Figure-3 Latticed Column

2. Steel Beam

Steel beam welded by steel plate or hot roller beam ,mainly used welded type H section beam,the top and bottom flange plate and web plate welded as H section beam .

Figure-4 Steel Structure Beam

3.Wind Column

Wind Column is the structure on the gable wall , wind column used for transfer the wind load on gable wall ,top through hinge connected with roof beam transfer to the roof system and as for the whole bent

load bearing structural,bottom throught connected with foundation transfer to foundation.

Arrangement method of wind column

arranged according Light Steel Plane Frame Structure : the foot of wind column hinge joint or rigid joint with foundation ,according the arrangement method ,roof load beared by steel frame and wind column together ,wind column bear the wind load and vertical load .

Figure-5 Wind Column

4.Crane Beam

crane beam is used to load the crane inside the workshp,crane beam is roadbed that support the driving of crane ,crane beam similiar as steel beam ,the diffirent is the web plate of crane beam welding stiffer plate which used provided support force when lifting cargo.

Figure-6 Crane Beam

5.C Purlin (C section steel)

C Purlin is C section steel that formed by galvanized steel sheet ,C Purlin widely used for fixed wall and roof panel

Figure-7 C Purlin

6.Z Purlin (Z section steel)

Z purlin with high strength ,save the steel materials ,quickly and easily for erection.Z purlin used for big span

7.Tie Beam

Tie Beam is the connecting rod in the horizontal length of building,tie beam used to resistant the longitudinal force.

8.Sag Rod

Sag rod used for tension and keep the purlin lateral stable,at same time arrange tension bracing in some area , it is sag rod plus sleeve pipe.

Figure-12 Sag rod

9.Flange Bracing

Flange bracing is the 45 degree diagonal bracing that connected with steel beam and purlin

10.Horizental Bracing

Horizental bracing is the horizental truss that arranged on side or middle of roof,horizental bracing used to enlarge the integral rigidity of roof and enlarge the lateral stability of frame.

11.Column Bracing

Column Bracing is ensure the overall stability of the building structure, improving the lateral stiffness and the transfer of vertical horizontal force ,transfer the vertical wind loading to column.

12.Wire mesh

Wire mesh used to support and stable the roof glass wool insulation materials.

Steel Structure roof system:

1)Single Color sheet , roof sheet used corrugated color sheet , such as V840Type

2)Single Color sheet + Glass wool insulation + wire mesh

Figure-17 Roof System

13.Insulation materials

Glass wool insulation used for heat preservation and insulation on roof .

Figure-18 Glass Wool Insulation Materials

14.Single Color sheet

Single color sheet also called corrugated color coated sheet which used as wall and roof of the industrial building ,warehouse,roof of the big span building.

Figure-19 Corrugated Color Sheet

15.Foot bolt

Foot bolt is J or L shape pre-embedded in concrete to connected with steel column,foot bolt fabricated as Q235B steel rod,the embedded depth is 25 times of diameter .

16.High Strength bolt

Friction type high-strength bolt :used for the connection of frame beam,column,solid web beam,the connection of crane beam in industrial workshop.

Bearing type high-tensile bolt :Can be used to allow a small amount of sliding in the static load structure or indirectly bear the load in the component of the shear connection.

Tensile strength bolt:Bolt tension, the fatigue strength is low, under the action of dynamic load, its carrying capacity is not more than 0.6P.

17.Normal Bolt

Normal bolt not used as bearing member ,used as connection during installation,normal bolt mainly used the connection of wall and roof purlin.

Figure-22 Normal Bolt

18.Self-tapping nail

Wall and roof panel of steel building fixed by self-tapping nail

Figure-22 Self-tapping nail

My experience with Browning Enterprise has been great. With a wide range of equipment and capabilities, they were able to get the best of the steel building components I asked for! Their quality is unmatched. Through their computerized software, they showed me some designs that could fit my requirements. Once the finalization was done, they were expertly able to manufacture stylish, functional, durable, and affordable components. I got blast-proof window frames from them for my upcoming project. The results were spotless and nicely cut, flattened, fabricated, and coated with perfection — a big thumbs up for their superb work.

回复删除Thanks for sharing the valuable Post

回复删除I recently had the pleasure of working with STEEL & GLASS on a construction project, and I must say, their expertise and professionalism exceeded my expectations. From the initial consultation to the final installation, their team demonstrated a high level of skill and attention to detail.

The installation process was seamless and efficient. The team worked diligently to ensure that every element was properly installed, paying close attention to even the smallest details. The result was a flawless finish that exceeded my expectations.

I highly recommend STEEL & GLASS for steel warehouse building or any construction or architectural project that requires steel and glass elements.

For all your steel construction needs, New Life Steel delivers cutting-edge steel structures that are strong steel structure and affordable. Their expert team designs and manufactures high-quality steel frameworks that cater to a variety of projects. Specializing in both large and small-scale construction, New Life Steel offers personalized services that meet your specific requirements

回复删除Steel structure manufacturers truly play a vital role in building durable and cost-effective solutions for industrial and commercial projects. With the right expertise and advanced fabrication techniques, steel structures offer unmatched strength, versatility, and longevity. If you’re looking for trusted solutions backed by quality manufacturing standards, Cell Com delivers top-notch steel structure manufacturing services tailored to your needs. Contact Cell Com today to discuss your project requirements!

回复删除Good knowledge and you can also read about our interesting blog here EN24 ALLOY STEEL

回复删除